Connected work zones are reshaping how construction sites communicate, protect workers, and improve traffic flow. By integrating real-time sensors, communication networks, and smart devices, these systems help drivers and operators navigate hazardous zones with better awareness and accuracy. Connected work zones offer proactive safety and help reduce delays caused by human error or outdated signage.

As infrastructure projects increase across the country, the demand for more intelligent work zone management grows. Today’s roadside crews need tools that communicate instantly with each other and with oncoming traffic, helping reduce collisions and improve project timelines. That’s where connected work zones step in to elevate the industry standard.

Table of Contents

Optimizing Lane Closures with Real-Time Data

Traditional lane closures rely on static signs and manual flagging, but connected systems introduce real-time monitoring to improve accuracy. Sensors track traffic flow, giving operators the data needed to decide when and where to close lanes for maximum efficiency.

This also benefits drivers. Instead of being surprised by sudden changes, they receive alerts through dynamic message boards or in-vehicle notifications. These real-time updates prevent last-minute maneuvers and reduce rear-end collisions—a leading cause of work zone accidents.

Smart Sensors Enhance Worker Safety

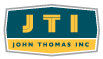

One of the most powerful benefits of connected work zones is their ability to detect intrusion. Using radar, LiDAR, or infrared sensors, crews can be immediately notified if a vehicle breaches a safety barrier or enters a restricted area.

When paired with alarms or wearable devices, these systems alert workers and give them a few critical seconds to react. That small window can make the difference between a close call and a life-threatening injury.

Reducing Human Error Through Automation

Connected work zones limit reliance on manual processes by automating flagger operations, signal control, and lane changes. This reduces the potential for human mistakes and provides a more consistent response to traffic fluctuations.

Advanced systems can adjust signal timing based on current conditions, improving vehicle throughput and reducing bottlenecks. These automated responses also minimize frustration for drivers, leading to safer and smoother commutes through active zones.

Cloud-Based Control Centers for Instant Oversight

Modern traffic control equipment increasingly connects to centralized cloud platforms. Supervisors can monitor multiple sites simultaneously, review analytics, and make remote adjustments without needing to be physically present.

This type of oversight also allows for predictive maintenance and system checks. If a sensor or sign malfunctions, alerts can be triggered before the issue causes safety concerns, making connected work zones more reliable.

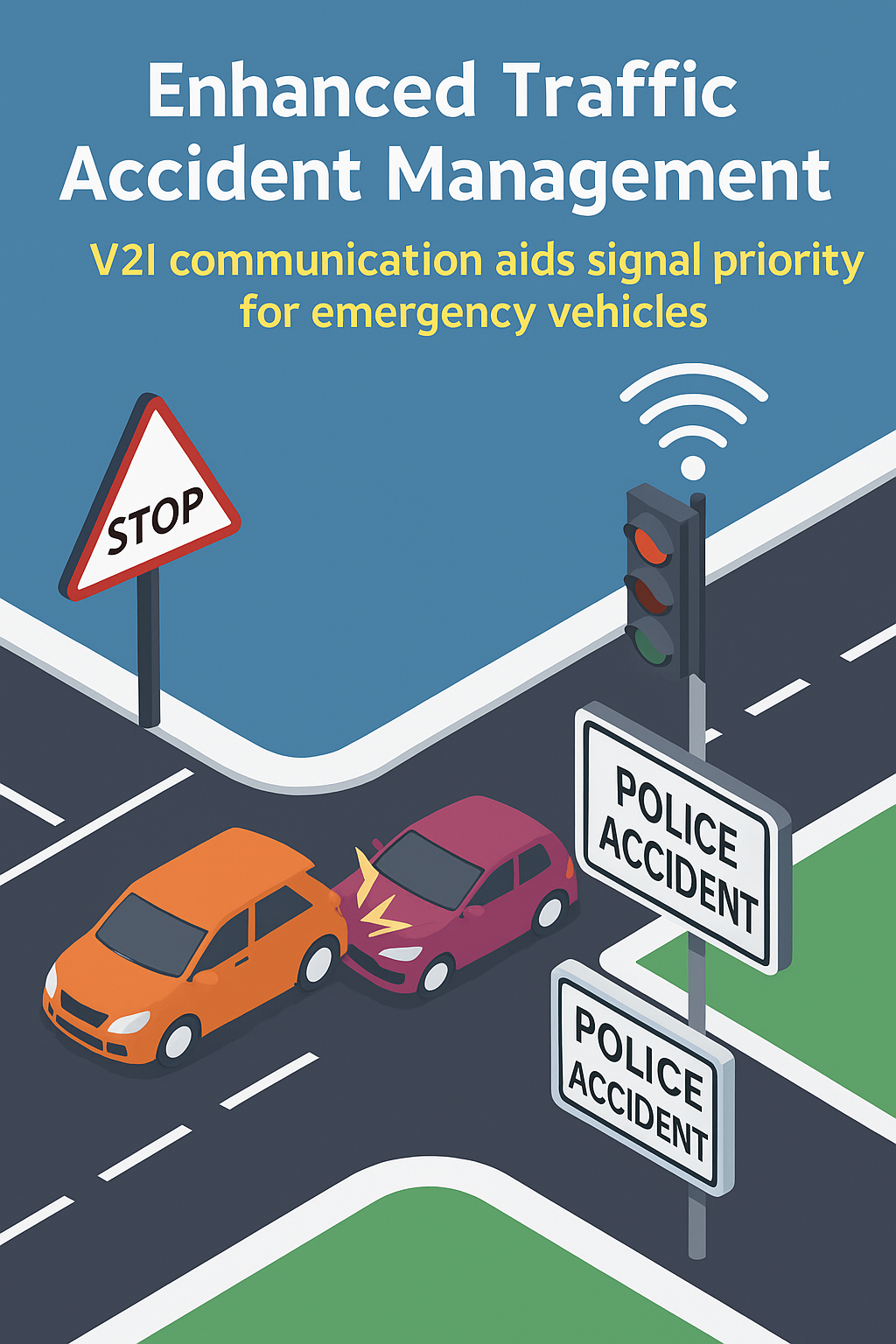

Vehicle-to-Infrastructure (V2I) Communication

A key component of connected work zones is their ability to interface directly with vehicles. V2I technology sends location-based alerts to drivers, informing them of speed limit changes, merging lanes, or active construction sites ahead.

This not only protects workers but also helps reduce crashes between vehicles. As more cars become connected, the importance of integrating with V2I systems will continue to grow.

Empowering Work Zone Alerts with Wireless Technology

Wireless communication is revolutionizing how alerts are issued in active work zones. Instead of relying on static signage or manual flagging, crews now deploy wireless beacons and sensors that send real-time alerts to connected vehicles and control centers. These devices can notify drivers about sudden lane shifts, reduced speed zones, or the presence of workers—enhancing driver awareness and minimizing last-second decisions that lead to accidents.

These technologies also provide vital information back to operators. Traffic speed, density, and even driver behavior can be tracked using wireless inputs, offering data that helps adjust work zone layouts dynamically. This adaptability significantly reduces congestion while boosting worker protection.

Harnessing AI and Predictive Analytics

Artificial intelligence now plays a role in connected work zones by predicting high-risk times and areas based on historical and real-time data. This lets planners and operators prepare for problems before they occur.

For example, if a stretch of road typically sees speeding violations during rush hour, alerts can be scheduled in advance to slow traffic. This intelligent forecasting protects both the crew and the public.

A Look Ahead: JTI’s Role in Connected Work Zone Technology

As this innovative technology continues to evolve, JTI is poised to support it with products designed for integration. From portable message signs to advanced sensor-enabled flagger systems, JTI offers traffic control solutions that can plug into connected infrastructure with ease.

These tools not only enhance safety but also contribute to smoother work zone operations, better data collection, and more satisfied project stakeholders. JTI remains committed to helping teams adapt to the future of smart work zones with flexible, scalable technology.